When it comes to industrial applications, the use of spray nozzles is a fundamental necessity for a wide range of operations. Among these operations, we can find the application of grease, an essential component of most machinery and equipment.

However, not all spray nozzles are created equal, and not all of them can provide the same level of precision and effectiveness when it comes to grease applications. Therefore, it is essential to understand the importance of specialized spray nozzles for these types of operations and how they can impact your productivity and bottom line.

To start with, we need to understand what grease is and why it is so critical for machine performance. Grease is a thick, semi-solid lubricant made from oil and a thickening agent. It is designed to protect moving parts from wear and tear by reducing friction and providing a barrier against dirt, dust, and water. In other words, greasing your machinery can help prevent costly breakdowns and extend the life of your equipment.

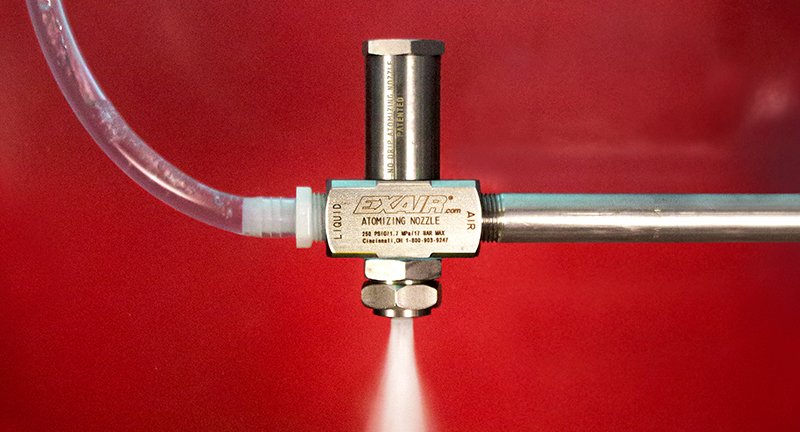

When it comes to applying grease, it is essential to use the right type of spray nozzle. Unlike other types of sprays, grease is thicker and requires a specific type of nozzle to ensure proper coverage and distribution. A specialized grease nozzle is designed to handle the unique characteristics of grease and provide accurate, efficient, and consistent application.

There are several reasons why using specialized spray nozzles for grease applications is crucial:

1. Versatility: Specialized grease nozzles can be designed to work with different types of greases and at various flow rates, pressure levels, and spray angles. This versatility ensures that your equipment receives the right amount of grease in the right location, regardless of its shape or size.

2. Efficiency: Using a specialized grease nozzle can help you reduce waste and save on grease costs. Specialized nozzles provide better control over the amount of grease applied, avoiding over-application and the need for frequent re-lubrication.

3. Precision: Grease nozzles provide precise coverage, ensuring that the lubricant reaches the target area while avoiding contamination and waste. This level of precision can help prevent equipment damage and minimize downtime due to maintenance or repairs.

4. Consistency: Using specialized grease nozzles ensures that each application is consistent, providing reliable results every time. This consistency helps to prevent issues such as uneven wear, which can degrade equipment performance over time.

In conclusion, when it comes to grease applications, using specialized spray nozzles can make a significant difference in the performance, efficiency, and longevity of your equipment. Choosing the right nozzle for your unique needs can help you maximize productivity, reduce costs, and minimize downtime due to maintenance and repairs.

If you have any questions about the importance of specialized spray nozzles for grease applications or need help choosing the right nozzle for your needs, contact us today at [insert company name here]. Our team of experts can provide you with the support and guidance you need to keep your operations running smoothly.