Products Details

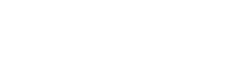

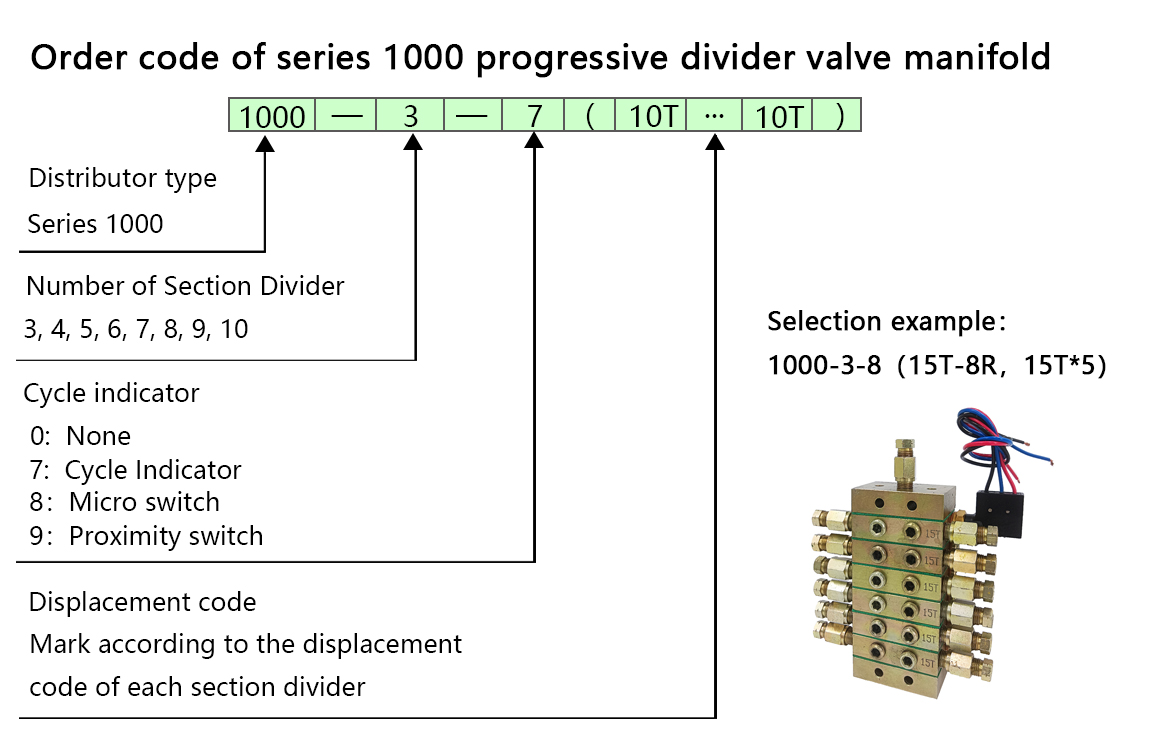

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.

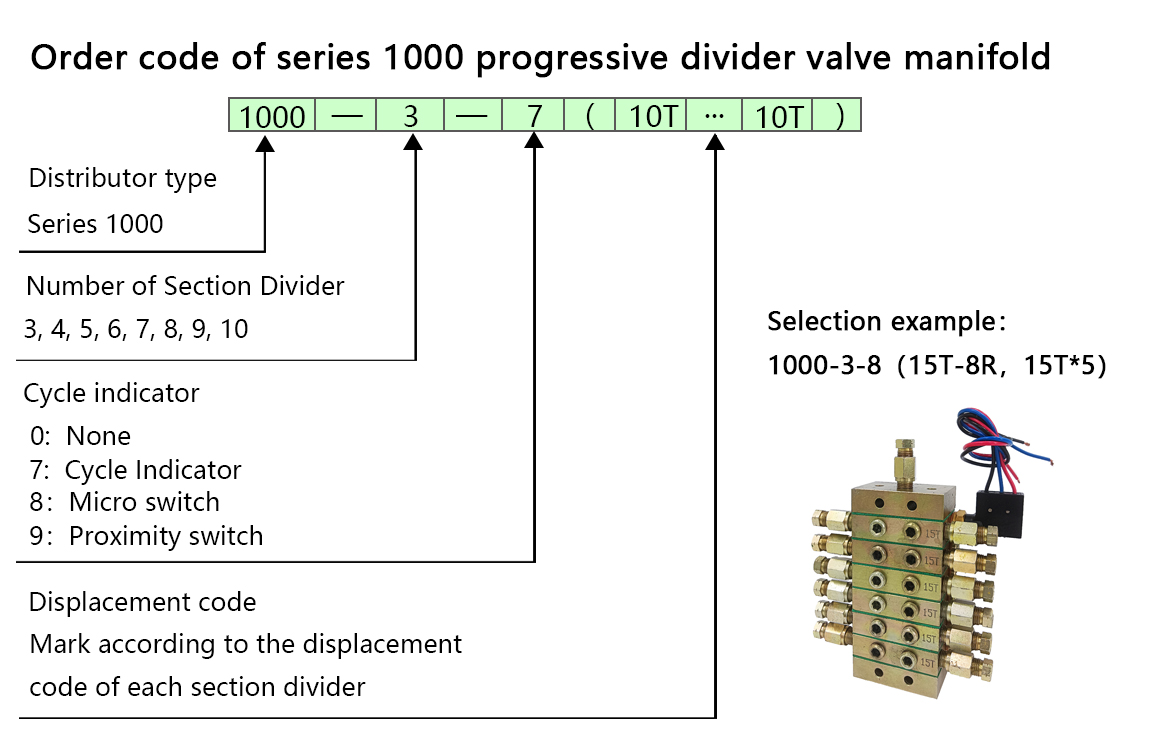

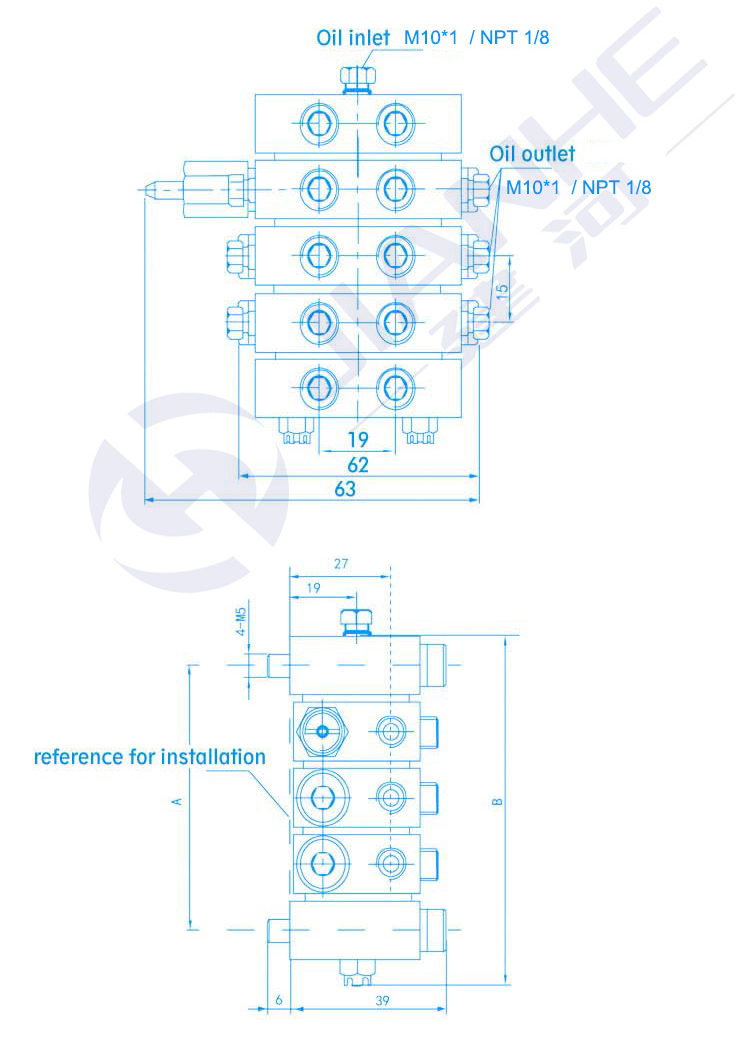

| MIN-MAX PRESSURE (MPA) | INLET SIZE | OUTLET SIZE | WORKING CHIP SIZE(MM) | INSTALL HOLE DISTANCE(MM) | INSTALL THREAD | LENGTH (A) | OUTLET PIPE DIA(MM) | WORKING TEMPERATURE |

| 1.4-16 | M10*1 NPT 1/8 | M10*1 NPT 1/8 | 54*32*14 | 18 | 4-M5 | A=32+N*14N CHIP NUMBER | STANDARD 6MM | ’-20℃ TO +60℃ |

| WORKING CHIPS | STANDARD FLOW | EACH CHIP OUTLET QUANTITY |

| 1000-05T | 0.08 | 2 |

| 1000-05S | 0.16 | 1 |

| 1000-10T | 0.16 | 2 |

| 1000-10S | 0.32 | 1 |

| 1000-15T | 0.24 | 2 |

| 1000-15S | 0.48 | 1 |

| 1000-20T | 0.32 | 2 |

| 1000-20S | 0.64 | 1 |

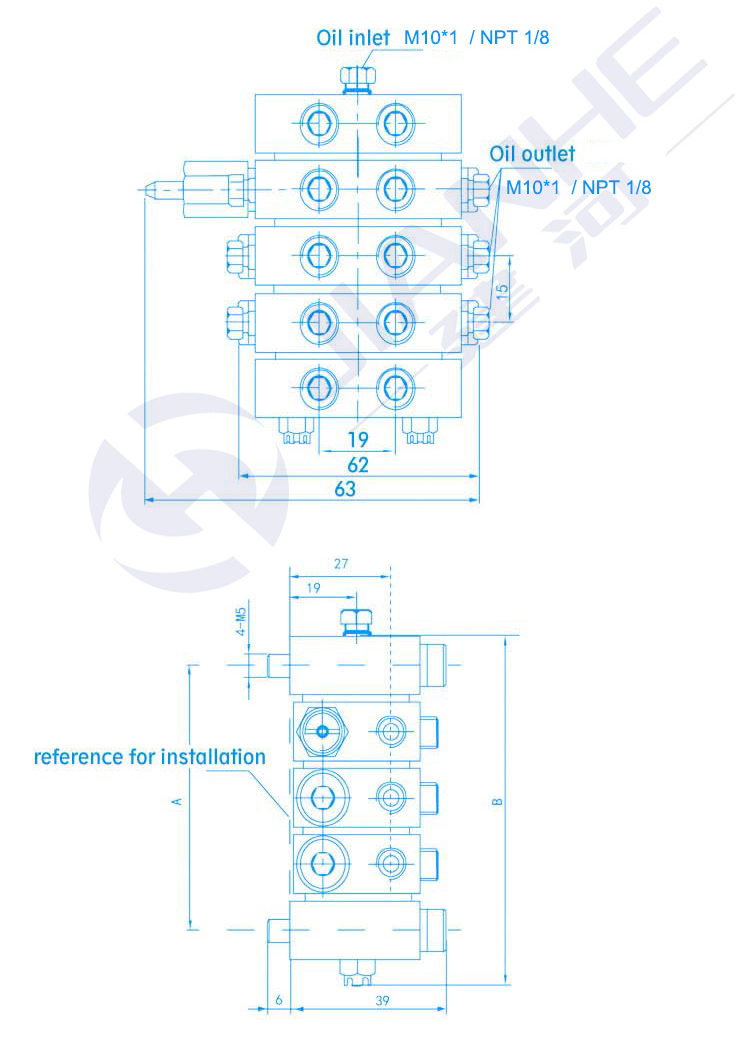

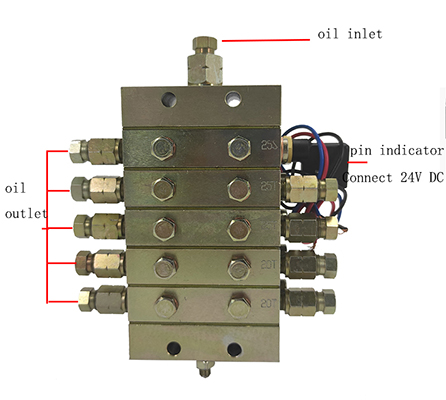

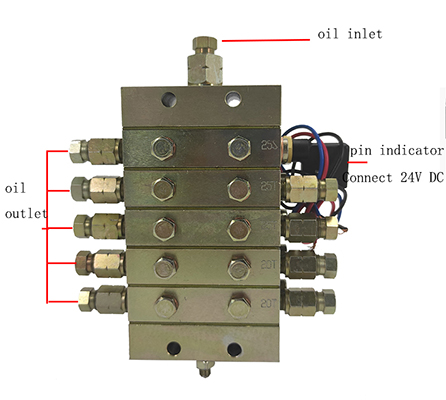

1. Progressive fueling sheet structure (by the first sheet, the work piece tails consisting of 3-8) 2. There are a variety of displacement options for the work piece, 0.08ml/cyc 0.16ml/cyc 0.23ml/cyvc, which is suitable for working conditions with changing displacement requirements. 3. Easy monitoring, configuration cycle or cycle indicator lever switch. 4. Use medium: lubricating oil to N68#, grease NLG1000#-2#. 5. Suitable for medium pressure working conditions, maximum nominal pressure: 16MPa 6. Each group of distributors can provide lubrication points: 3-16 points.The advantage of this dispenser over the dispensers of other manufacturers is that it is equipped with a pressure holding device, which can reliably ensure that the pressure of the dispenser is sufficient. Under the circumstance, there will be no problem of oil leakage. At the same time, the piston drain groove is narrower than other types of distributors, and its sealing surface is larger. It is in the same type of progressive distributor. In the middle, the sealing performance is good, and the O-ring is installed between the plates to enhance the sealing performance. Therefore, the suitable medium for the distributor is not only grease, but also Used for lubricating oil with viscosity greater than N46. This dispenser is accurate in measurement, and different displacements can be combined arbitrarily according to the needs of lubrication. The distributor is easy to monitor, only need to monitor The working status of any oil outlet on the distributor can effectively judge whether the entire group of distributors is working normally. Distributor technical indicators: 1. Applicable lubricant range (marked temperature): lubricating oil is greater than or equal to No. N68, grease NLGI000#~2# 2. Maximum nominal pressure: 16MPa 3. Standard displacement: 0.08ML/CYC~0.48ML/CYC 4. Working environment temperature: -20℃~+60℃ (antifreeze grease should be used at low temperature) 5. The highest circulation rate of the plunger pair equipped with a mechanical circulation indicator: 60CYC/MIN 6. The highest circulation rate of the plunger pair: 200CYC/MIN 7. The number of slices of each group of distributors: 3-8 slices 8.Each group of distributors can supply lubrication points: 3-16 points 9.The best pipe diameter and length of the distributor output: 4MM, 0.5 to 2.5M long The picture shows a grease distributor (as we call it), its function is to progressively discharge grease. The so-called progressive type means that after one oil outlet has greased out once, the next oil outlet will emit grease. Its oil outlet is 0.08cc-0.48cc each time.There is a black part in the picture is a Pin indicator, connected to your mechanical equipment can detect whether the oil port is faulty, you can install it selectively.

The picture shows a grease distributor (as we call it), its function is to progressively discharge grease. The so-called progressive type means that after one oil outlet has greased out once, the next oil outlet will emit grease. Its oil outlet is 0.08cc-0.48cc each time.There is a black part in the picture is a Pin indicator, connected to your mechanical equipment can detect whether the oil port is faulty, you can install it selectively.

Oil lubrication systems.,

High volume lubrication pump,

YS- oil brush,

Industrial Oil pump TOP- A,

RH distributor for lubrication systems,

Industrial lube pumps,

Pengertian Lubrication System,

Lubrication system clamp,

Industrial pump systems,

ZDY- Z grease pump,

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.

The picture shows a grease distributor (as we call it), its function is to progressively discharge grease. The so-called progressive type means that after one oil outlet has greased out once, the next oil outlet will emit grease. Its oil outlet is 0.08cc-0.48cc each time.There is a black part in the picture is a Pin indicator, connected to your mechanical equipment can detect whether the oil port is faulty, you can install it selectively.

The picture shows a grease distributor (as we call it), its function is to progressively discharge grease. The so-called progressive type means that after one oil outlet has greased out once, the next oil outlet will emit grease. Its oil outlet is 0.08cc-0.48cc each time.There is a black part in the picture is a Pin indicator, connected to your mechanical equipment can detect whether the oil port is faulty, you can install it selectively.