Products Details

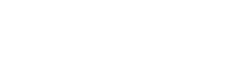

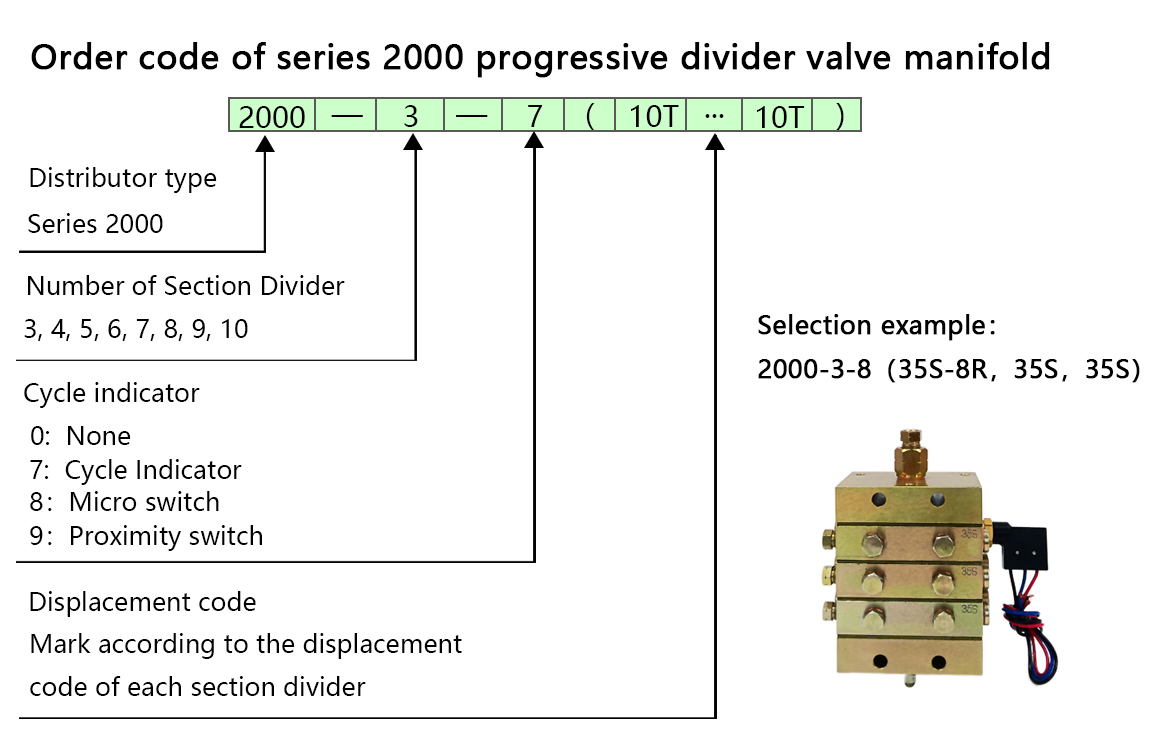

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.

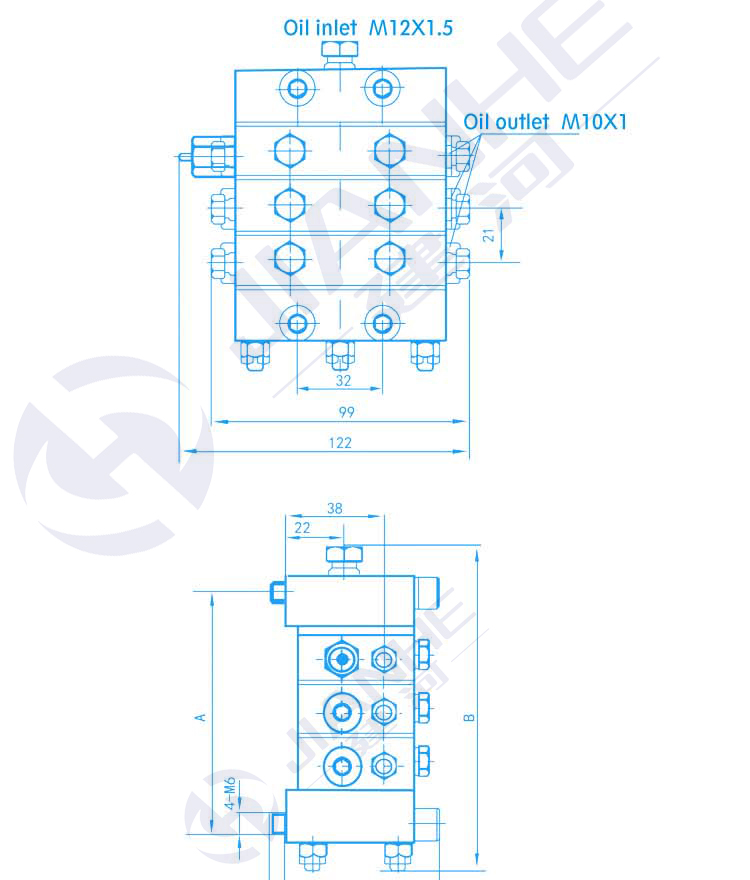

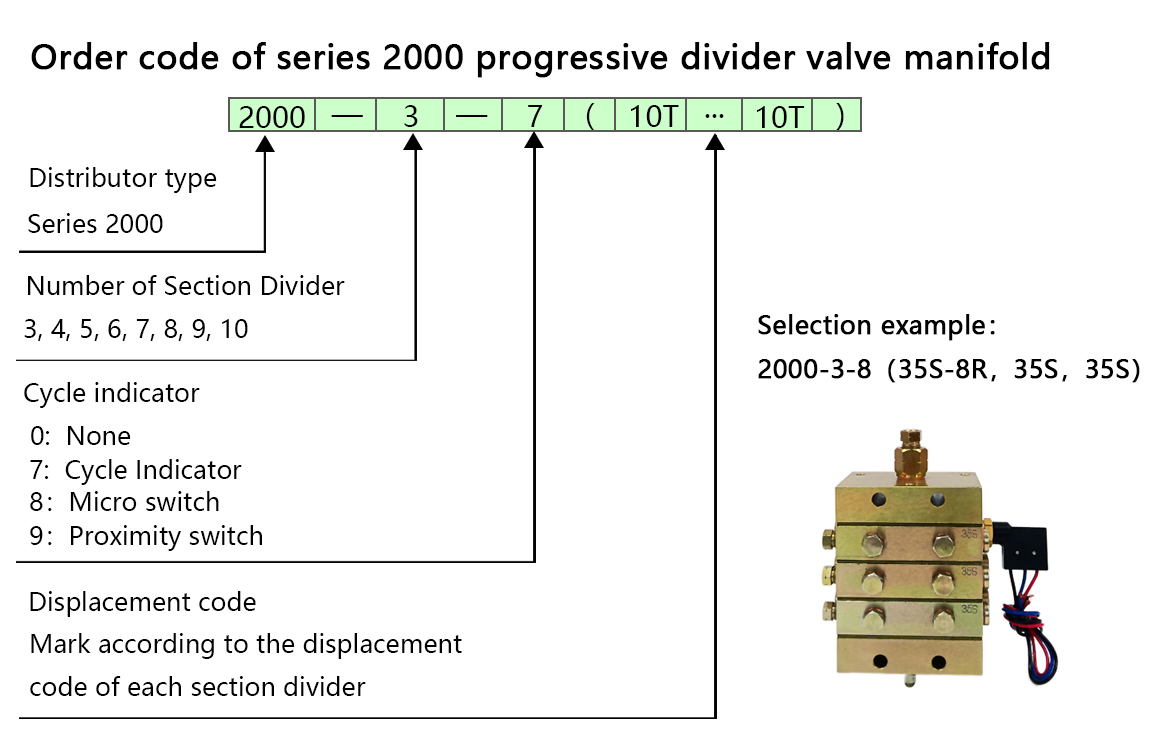

| MIN-MAX PRESSURE (MPA) | INLET SIZE | OUTLET SIZE | WORKING CHIP SIZE(MM) | INSTALL HOLE DISTANCE(MM) | INSTALL THREAD | LENGTH (A) | OUTLET PIPE DIA(MM) | WORKING TEMPERATURE |

| 1.4-25 | M12*1.5 | M10*1 | 80*45*19 | 32 | 4-M6 | A=32+N*20.5N CHIP NUMBER | STANDARD 6MM | -20℃ TO +60℃ |

| WORKING CHIPS | STANDARD FLOW | Each chip outlet quantity |

| 2000-10T | 0.16 | 2 |

| 2000-10S | 0.32 | 1 |

| 2000-15T | 0.24 | 2 |

| 2000-15S | 0.48 | 1 |

| 2000-20T | 0.32 | 2 |

| 2000-20S | 0.64 | 1 |

| 2000-25T | 0.4 | 2 |

| 2000-25S | 0.8 | 1 |

| 2000-30T | 0.48 | 2 |

| 2000-30S | 0.96 | 1 |

| 2000-35T | 0.56 | 2 |

| 2000-35S | 1.12 | 1 |

Progressive oil supply, slice structure (consisting of the first film and 3-10 working film tails) is suitable for high pressure working conditions, the maximum pressure: 25Mpa. Standard displacement: 0.16-1.12ml/cyc in various specifications. It is easy to monitor, and can be configured with cycle indicator rod or cycle switch. Use medium: lubricating oil≥N68#, grease NLGI000#-2#. Suitable for medium pressure working conditions, the maximum nominal pressure: 16Mpa. Lubrication points available for each group of distributors: 3-20 points.

PLH oil fittings,

Bath Lubrication System,

Mechanical oil pumps,

Micro Lubrication System,

Oil filtration system,

High-pressure dosing system,

Stern Tube Lubrication System,

Water pressure booster pump,

Press Lubrication Systems,

pipe,

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.

1. Section divider displacement code T indicates that the working piece is the oil outlet on both sides; S indicates that the working piece is a single-sided oil outlet, and the suffixes L and R indicate the direction of the outlet. 2. Under any circumstances, the user shall not block the outlet of the valve to avoid damage to the valve due to overpressure.