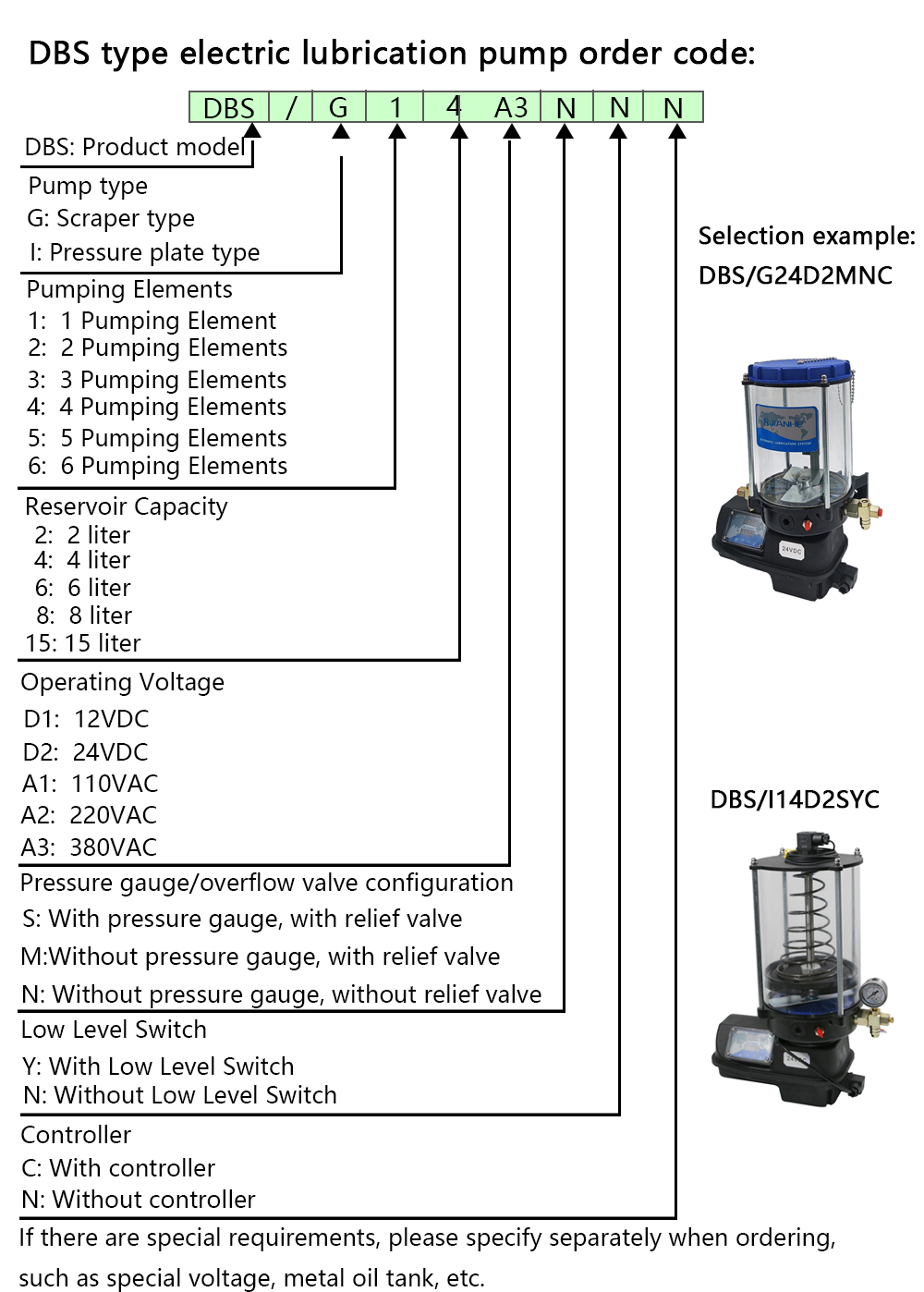

DBS electric grease pump is an electric plunger lubrication pump with compact structure, excellent performance and high output pressure. It can be equipped with up to 6 pump units at the same time. In SLR (damped lubrication system), the distributor of each oil outlet can distribute the grease to each lubrication point proportionally through the control button (CU). In PRG (Progressive Lubrication System), the distributor of each oil outlet constitutes an independent lubrication system. Under the control of the program controller, grease can be delivered to each lubrication point in a fixed and quantitative manner. If equipped with an oil level switch, a low oil level alarm can be realized, and the motor protective cover can be dust-proof and rain-proof. The pump is widely used in engineering, transportation, machine tools, textiles, light industry, forging, steel, construction and other machinery.