For use in multi-line and progressive lubrication systems

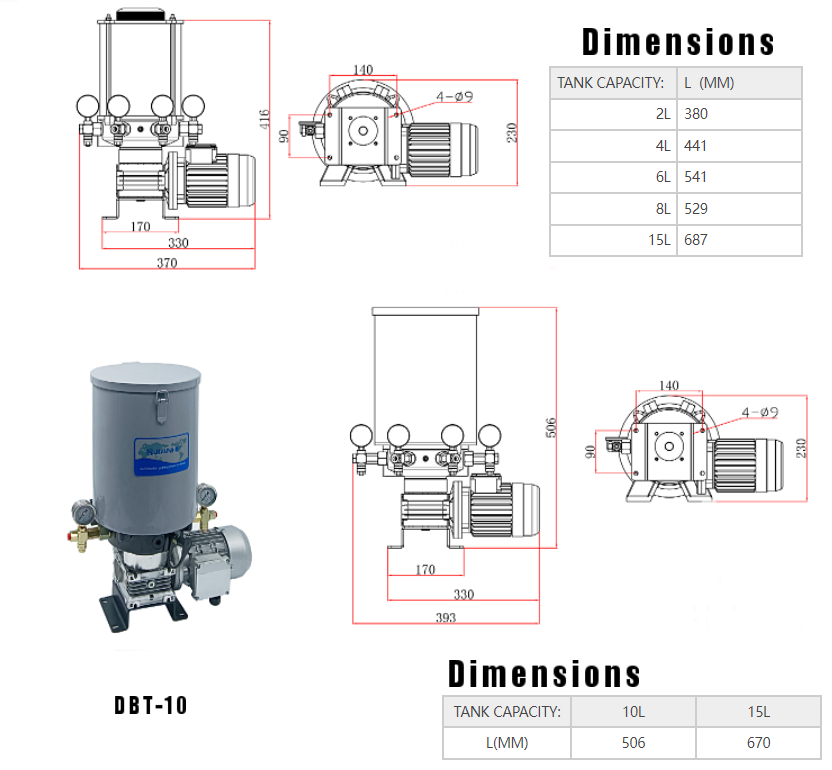

The high-pressure, multi-line pump can supply lubricant directly to lubrication points or can be used as a centralized lubrication pump in large-sized progressive systems. It can drive up to five elements, which are available in varying sizes for optimum adjustability. The pump’s drive and eccentric shaft design, high-efficiency worm gear, minimal number of parts and multi-range motor provide several advantages. DBT pumps are available with a three-phase flange mount and multi-range motor or with a free shaft end for use with other motors. Various gear ratios and reservoir sizes with or without level control are offered.

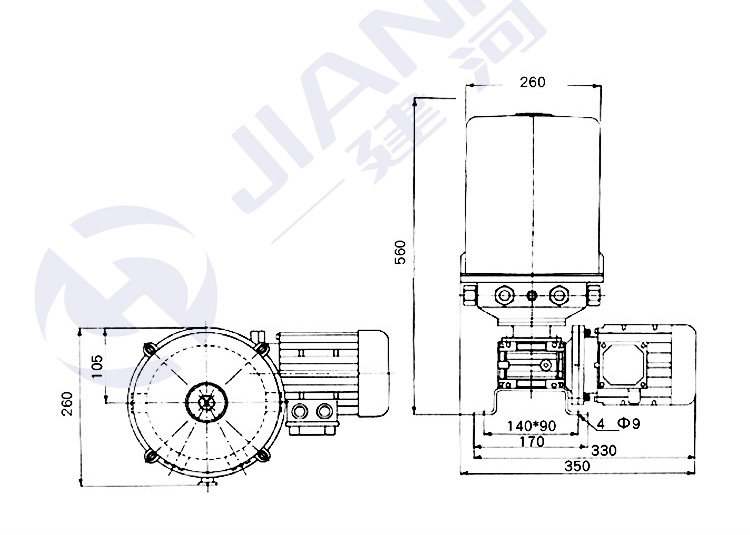

After the motor is decelerated by the worm gear,the eccentric wheel is continuously driven to rotate counterclockwise , and the eccentric wheel pushes the plunger to reciprocate to pump and pump grease . The rotation of the scraper plate can press the lubricant into the suction zone of the pump unit, and can efficiently discharge bubbles. Rated working pressure: s 25Mpa (adjustable) Lubrication pump rated displacement: single oil outlet 1.8m/min Lubrication pump input power: 380V AC/50HZ Motor power: 90W Tank capacity: 15 liters Operating temperature : -20'C --- +55C Applicable medium:NL GI 000---2# grease, it is recommended to adjust the viscosity of the medium according to the change of temperature.

After the motor is decelerated by the worm gear,the eccentric wheel is continuously driven to rotate counterclockwise , and the eccentric wheel pushes the plunger to reciprocate to pump and pump grease . The rotation of the scraper plate can press the lubricant into the suction zone of the pump unit, and can efficiently discharge bubbles. Rated working pressure: s 25Mpa (adjustable) Lubrication pump rated displacement: single oil outlet 1.8m/min Lubrication pump input power: 380V AC/50HZ Motor power: 90W Tank capacity: 15 liters Operating temperature : -20'C --- +55C Applicable medium:NL GI 000---2# grease, it is recommended to adjust the viscosity of the medium according to the change of temperature.